Underwater Propeller Repair

Underwater repairs, maintenance and inspection for the international merchant fleet.

Damaged propeller problems

It is difficult to estimate the increase, but even a small percentage of extra fuel consumption will quickly exceed the repair price of underwater propeller repair.

Several problems arise from damaged or bend propeller blades. Due to the bent section of the blade, the pitch of this blade has increased and for sure your fuel consumption will rise. Even if you don’t notice any significant vibrations, because the propeller is now running heavier.

The fact that one (1) blade has a higher pitch, results in an unevenly distributed pressure on the propeller. The shaft installation was not designed to handle this.

The engine has to work harder, which could create the risk of overloading. Due to the bent section, the water does not flow smoothly along the blade surface, so there is a chance for further damage due to cavitation.

Sometimes an indication of this phenomenon is an increased level of propeller noise, but it is possible that you do not notice this during sailing at all, while cavitation damage still progresses.

Underwater Propeller Repair in 24 hrs

The total time for underwater propeller repair are normally under 24 hrs, with no drydocking or down time. It’s a cost effective solution that is guaranteed to get you back on schedule fast. Feel free to contact us!

FN Diving Underwater Propeller repair options

- Underwater propeller straightening

- Crack repair and propagation control

- Static balancing

- Replacement of Controllable Pitch Blades and Blade seals

- Restoration of Hydrodynamic edge tours

- Pitch and Camber alterations

- Full Thruster repairs and complete unit replacement

After detailed underwater inspection by our underwater propeller technicians and getting a clear overview of the damages and their proportional effect on the final Repair, we can either perform;

Propeller Straightening

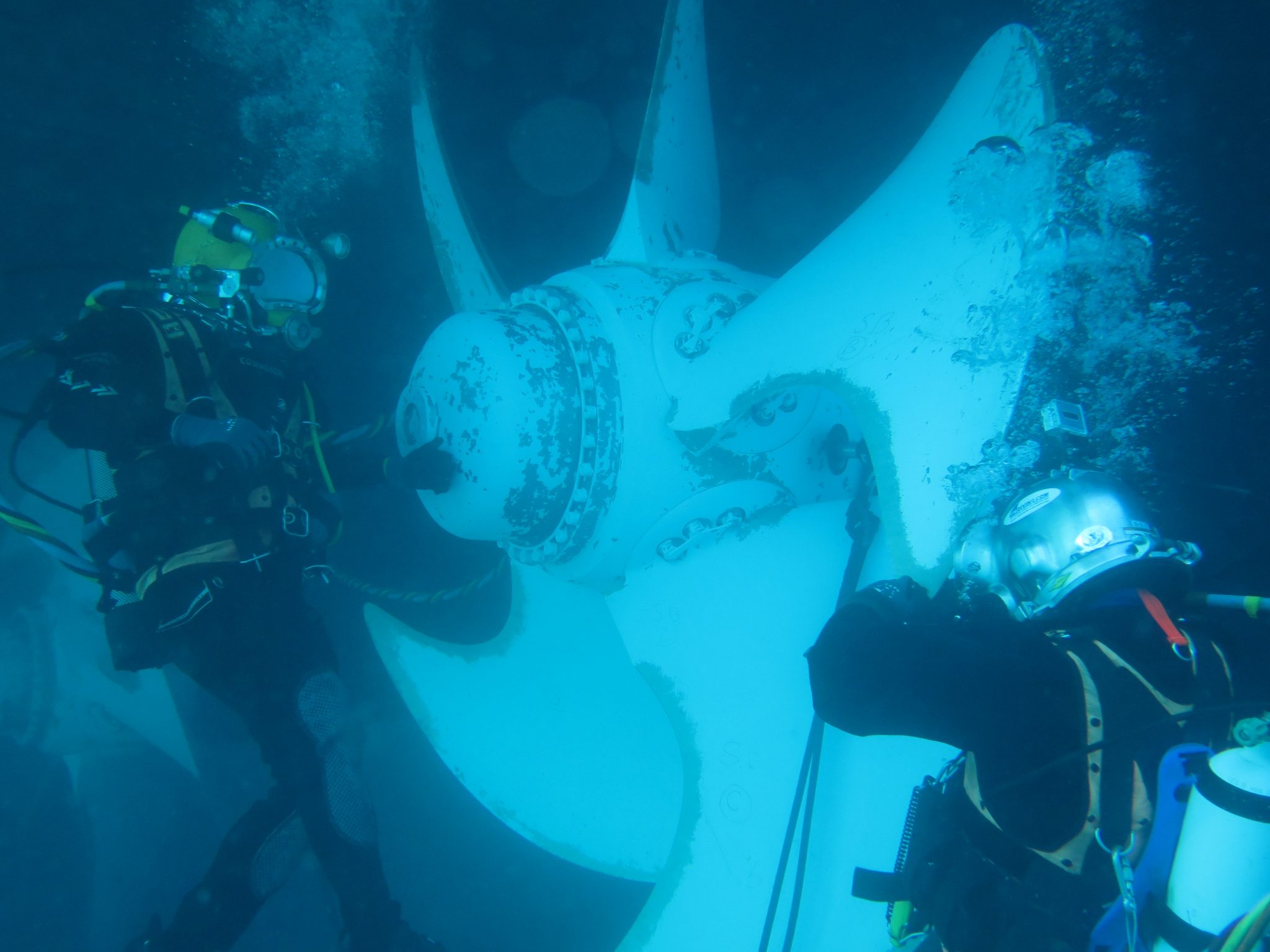

By using up to the biggest underwater propeller repair apparatus in the world, specially designed for severe bend blades due to ice or impact damage.

Damaged propeller blades are straightened completely underwater by using a cold static load press by an FN Diving operations team bringing the blades to their original design possible to restore optimum performance and efficiency of the propeller.

These operations are normally done underwater without the ship to ballast the damaged propeller section out of the water.

Underwater Propeller Blade Cutting/Cropping

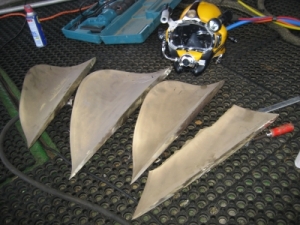

If straightening is not an option anymore or the static balance will be lost due to a missing piece on one of the blades, the affected area on the blades will be cropped to restore optimum performance and efficiency of the propeller.

This is done with the swiftest underwater diamond cutting equipment specially designed for propeller blade cutting repair in the World.

To repair your ship’s propeller can provide a number of benefits, including cost savings, improved performance, increased safety, quick turnaround, and environmental sustainability.

For more info on underwater Propeller repair contact FN Diving Rotterdam or Algeciras

At FN Diving, we specialize in comprehensive underwater propeller repair services, ensuring vessels maintain optimal performance without the need for drydocking. Our team of certified divers and technicians is equipped to handle a wide range of propeller issues efficiently and effectively.

Common Propeller Issues

Propeller damage can manifest in various forms, each impacting vessel performance:

•Bent Blades: Often resulting from collisions with submerged objects or ice, bent blades can increase fuel consumption and cause vibrations.

•Cracks: Stress or impact can lead to cracks, which, if untreated, may propagate and compromise structural integrity.

•Corrosion: Prolonged exposure to seawater can cause corrosion, weakening the propeller material.

•Cavitation Damage: Irregular water flow can create vapor bubbles that collapse on the blade surface, leading to pitting and erosion.

Our Repair Services

FN Diving offers a suite of underwater propeller repair solutions tailored to address these issues:

Underwater Propeller Straightening: Utilizing advanced cold static load press machines, we can straighten severely bent blades underwater, restoring them to their original design and ensuring optimal performance.

Crack Repair and Propagation Control:

Our technicians perform meticulous inspections to identify cracks and employ specialized techniques to repair and halt further propagation, maintaining the propeller’s structural integrity.

Static Balancing:

Ensuring the propeller’s balance is crucial for smooth operation. We conduct on-site static balancing calculations to minimize vibrations and enhance efficiency.

Replacement of Controllable Pitch Blades and Blade Seals:

For vessels equipped with controllable pitch propellers, we offer underwater replacement of damaged blades and seals, ensuring seamless operation without the need for drydocking.

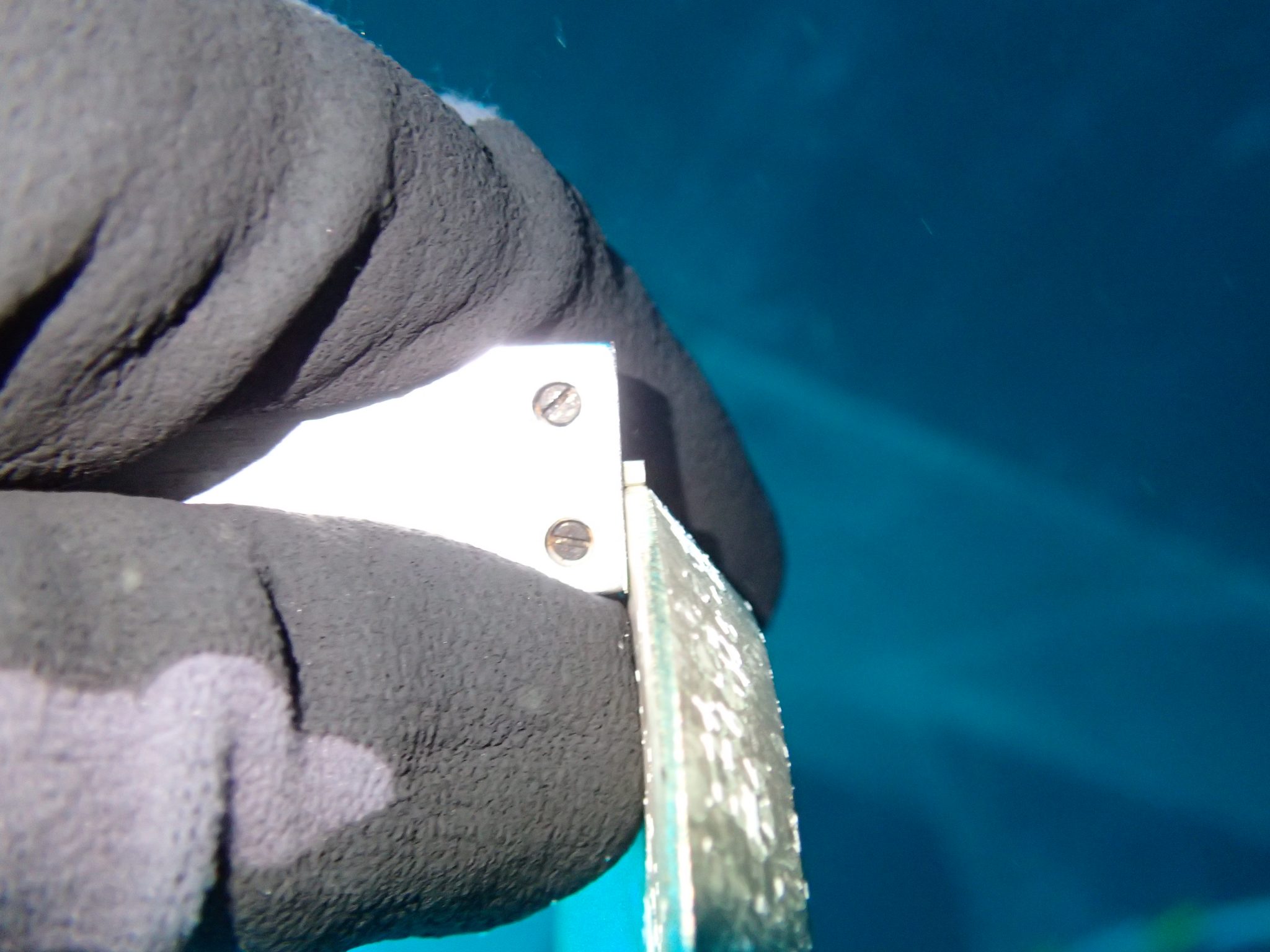

Restoration of Hydrodynamic Edge Contours :

Damaged edges on propeller blades can disrupt water flow, reducing efficiency. We restore these contours to their original specifications, improving performance and reducing fuel consumption.

Pitch and Camber Alterations on Ship Propeller blades: Adjusting the pitch and camber of propeller blades can correct issues like engine overload or cavitation. Our team uses precise underwater pitch meters to make these adjustments accurately.

Full Thruster Repairs and Complete Unit Replacement: Beyond propellers, we handle comprehensive thruster repairs and replacements, ensuring all aspects of your vessel’s propulsion system are in optimal condition.

Our Process

Upon receiving a service request, our process involves:

•Detailed Underwater Inspection: Certified propeller technicians assess the extent of damage using advanced equipment.

•Customized Repair Plan: Based on the inspection, we develop a tailored repair strategy, considering factors like damage severity, propeller type, and vessel schedule.

•Execution: Our team mobilizes swiftly, often completing repairs in under 24 hours, minimizing vessel downtime.

•Post-Repair Assessment: We conduct thorough evaluations to ensure the repair’s success and the propeller’s optimal performance.

Why Choose FN Diving?

•Experience: With years of expertise in underwater ship repair, we’ve handled a diverse range of propeller issues across various vessel types.

•Efficiency: Our streamlined processes and advanced equipment enable us to perform repairs swiftly, often aligning with tight vessel schedules.

•Class Approved Propeller repair: Our repair methods are class-approved, ensuring compliance with international maritime standards.

Based in Rotterdam and Algeciras, we offer worldwide services, ready to deploy our teams wherever they’re needed.

At FN Diving, we’re committed to keeping your vessels operational and efficient. Our underwater propeller repair services are designed to minimize downtime and maximize performance, ensuring your maritime operations remain smooth and cost-effective.